BRIEF SUMMARY NOTES

There are two types of Polymerization:

- Addition Polymerization

- Condensation Polymerization

Addition Polymerization

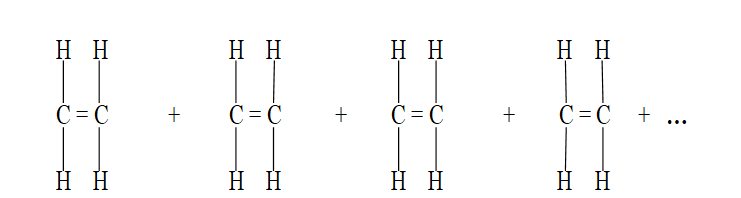

Addition Polymerization is the process where small unsaturated monomer (alkene ) molecules join together to form a large saturated molecule.

Only alkenes undergo addition Polymerization.

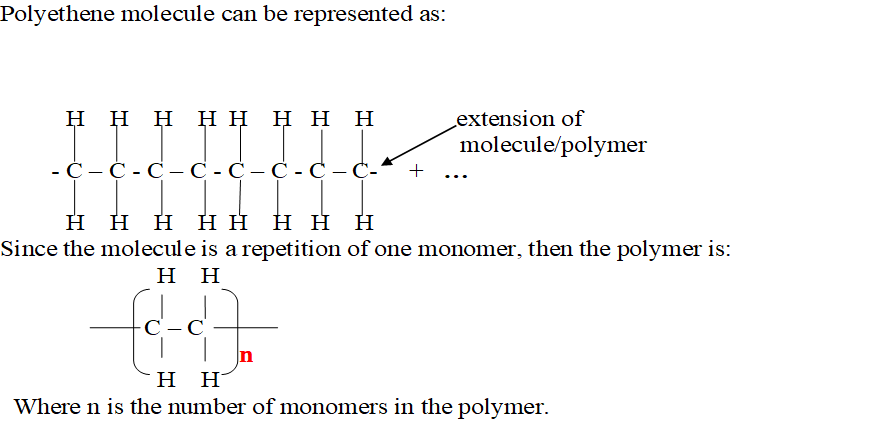

Addition polymers are named from the alkene/monomer making the polymer and adding the prefix “poly” before the name of the monomer to form a Polyalkene.

During addition Polymerization

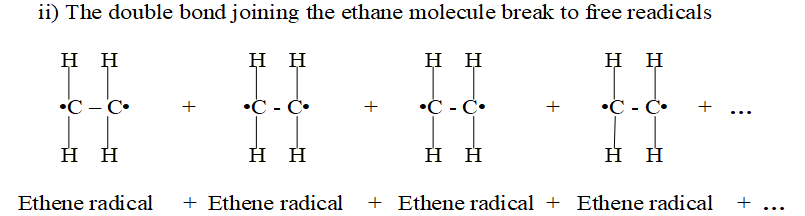

(i) The double bond in alkenes break.

(ii) Free radicals are formed.

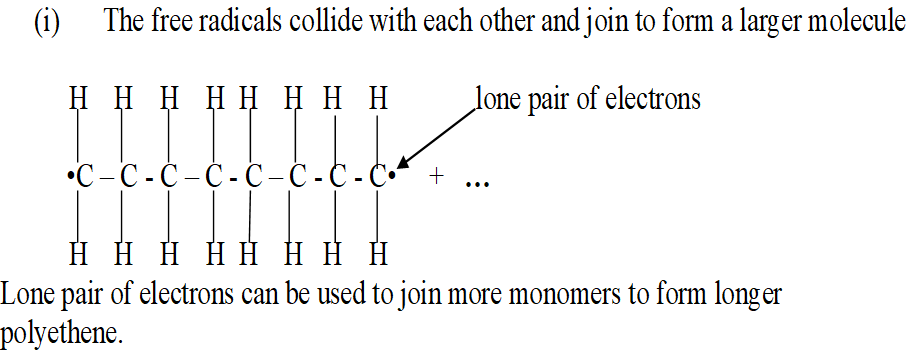

(iii) The free radicals collide with each other and join to form a larger molecule.

The more the collisions the larger the molecule.

Condensation Polymerization is where two or more small monomers join together to form a larger molecule by elimination of a simple molecule (usually water OR ammonia).

Condensation polymers acquire a different name from the monomers as the two monomers are two different compounds